FACTORY 4.0

LEADING THE WAY

Alesol Equipments has expertise in implementing Factory 4.0 technologies in all three groups:

- Virtual

- Motion

- Decision

In addition to improvements associated with automating a process, these technologies will provide the benefits of being:

- Predictive

- Corrective

- Adaptive

By interconnecting cells of manufacturing, automation, transportation and business processes, Alesol Equipments will help guide your journey to Factory 4.0 and beyond.

VIRTUAL TECHNOLOGIES

- Real time emulation of mechanical and controls systems

- Virtually create a digital twin in CAD

- Off-line robot programming/validation of machine sequences

- Virtually debugging of PLC logic

- Event based simulations to validate cycle times

- Proves complex processes prior to machine release

- Visualizes human to machine interfaces

- Allows users to experience machine operation and validate potential issues

- Enhances remote support and training

- Collects real life data

- Enhances human and machine decision making

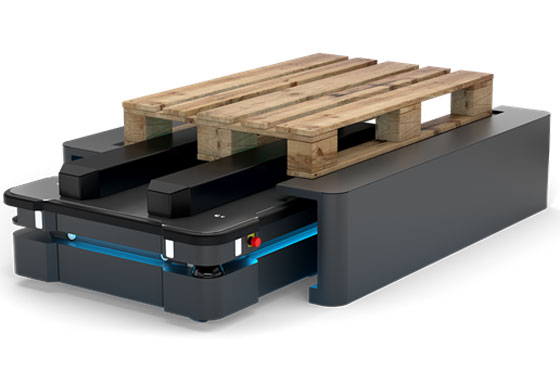

MOTION TECHNOLOGIES

- Automates processes and feeds data for decisions

- Automates transportation of products

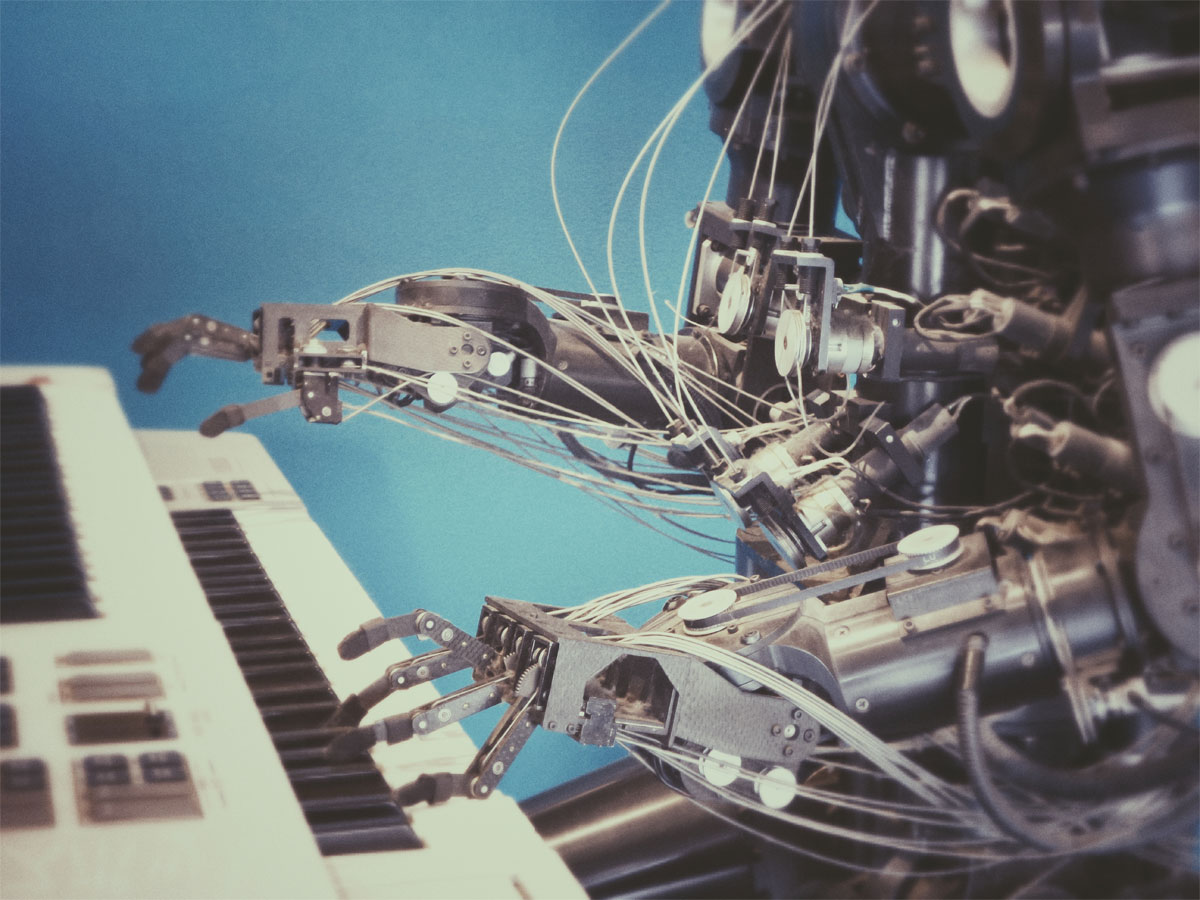

DECISION TECHNOLOGIES

- Smart devices that can make some decisions and feed data to other controllers

- Databases and software networking solutions that store process data for analysis by a controller or AI

- ‘Bots’ are software programs designed to perform a repetitive local task and feeds data to a central controller or AI

- Developing technology that simulates a working mind and makes use of all of the above to optimize processes and interfaces to suppliers and customer systems