Plate-Fin Type Heat Exchangers

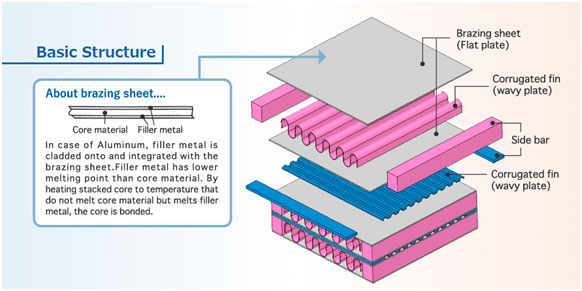

Our heat exchangers composes of corrugated fin and separation plate which are stacked and brazed. Comparing to the other type of heat exchangers, by enlarged heat transfer area, this type of heat exchanger becomes more compact and lighter. We can produce from large to small heat exchanger, and take flexible material choices, such as aluminum alloy, and stainless steel etc.

Features

Comparing to the other type of heat exchangers, if plate-fin type is applied, your heat exchanger can achieve compact and light weight in general, because heat transfer area is enlarged and heat transfer area per volume becomes large. Especially, in case of gas-gas heat exchange process, heat exchanger which is designed by enlarged heat transfer area becomes significantly compact and light weight.

Model case: Comparison between “Shell & Tube” and “Plate-Fin”In comparison with Shell & Tube heat exchangers, the following benefits are expected for our Plate-Fin heat exchangers;

- Smaller installation space.

- Simplification of support structure for heat exchanger

- Reduction in power consumption of compressor

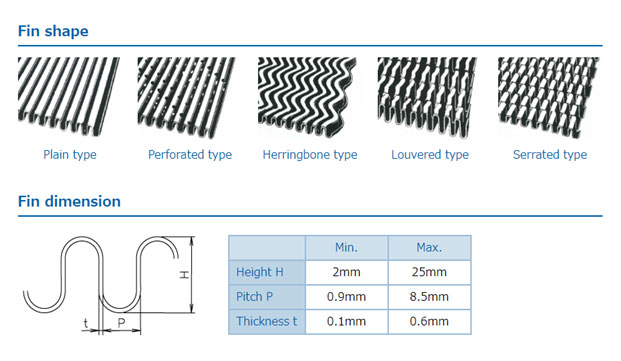

For accommodating various customer requests, we assort about 300 kinds of corrugated fin, and offer most suitable selection for customer specification.

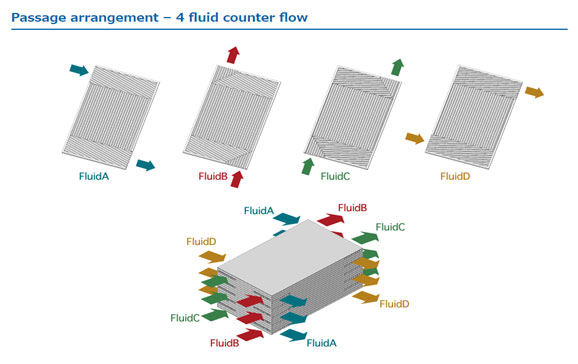

Due to structure of plate-fin type, multi fluid heat exchange is possible. You can reduce piping and installation space. (Up to 15 fluid possible)

Depending on fluids or the other conditions, we can propose appropriate material, not only aluminum alloy, but also stainless steel, nickel alloy, and titanium alloy.